Electrification Initiatives

Technological capabilities behind the evolution of the e-Axle, the heart of EVs

Electric vehicles (EVs), plug-in hybrid electric vehicles (PHEVs), fuel cell electric vehicles (FCEVs), and other electrically powered vehicles are on the rise. This trend is spreading to commercial vehicles as well. The electrification of commercial vehicles is being promoted to reduce environmental impacts, improve fuel efficiency, and enhance driving performance.

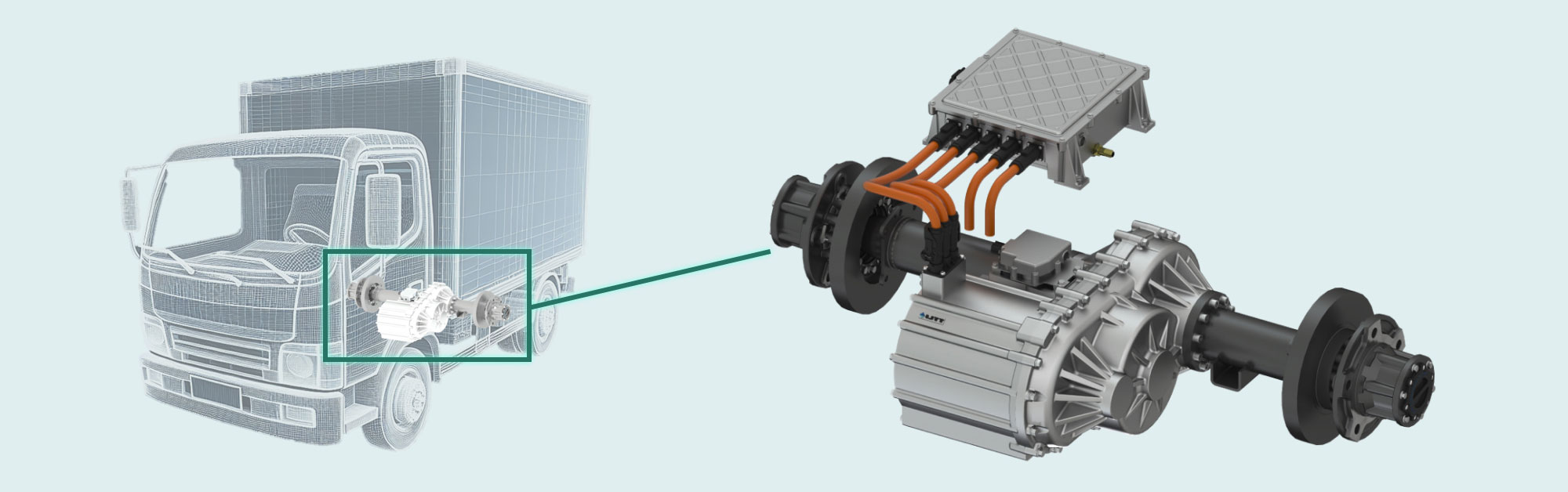

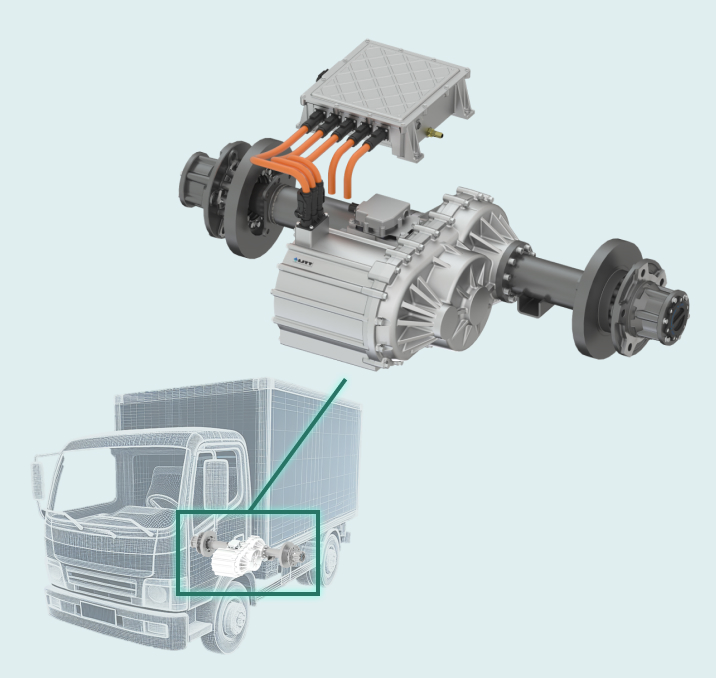

We have developed and commercialized the e-Axle, a drive unit that integrates a motor, reduction gear, differential, park lock, and drive shaft.

Features of IJTT’s e-Axle

Combining high-speed rotation, low noise, and durability

We aim to improve product appeal by adding electrification technologies to our drivetrain products. It combines high-speed gear lubrication technology, noise reduction technology, and reliable durability.

Driveshaft developed exclusively for e-Axle

Applying technology developed through constant-velocity joints, a driveshaft structure was designed and adopted to achieve high performance while limiting the amount of heat generated.

It also supports large angles of intersection and changes in payload that are unique to trucks and other commercial vehicles.

Evaluation and testing system that takes into account the optimization of the entire vehicle

In addition to basic testing of e-Axle, actual vehicle testing is also conducted to ensure that the actual driving performance is taken into account in the development of e-Axle. We are also adding and improving evaluation equipment as needed to confirm its practicality.

Product lineup

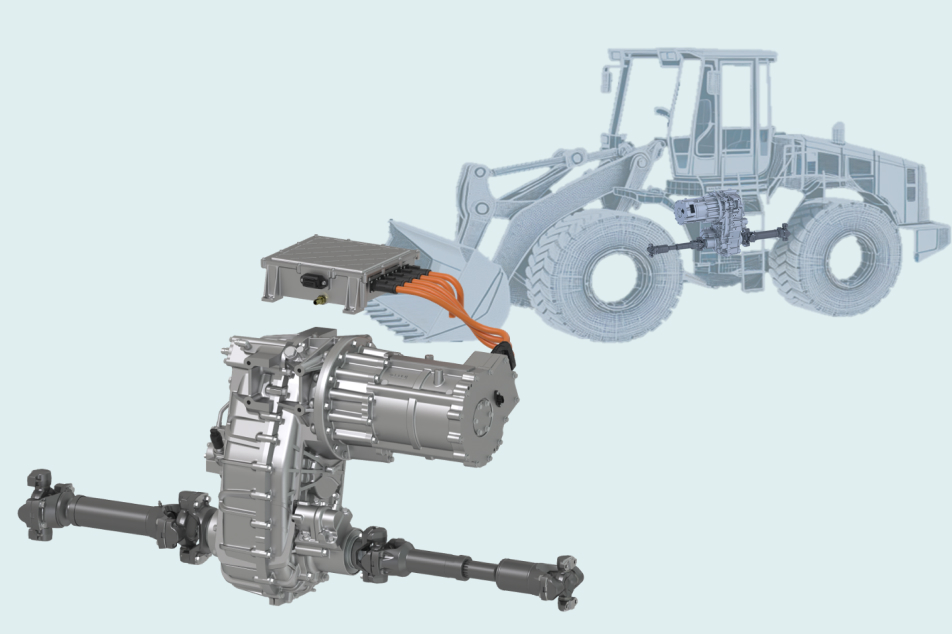

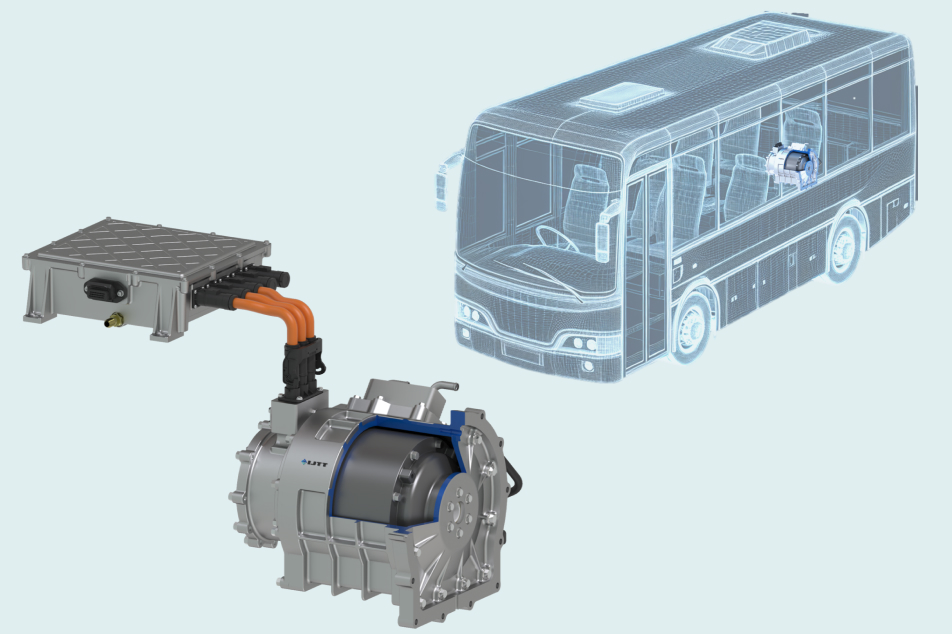

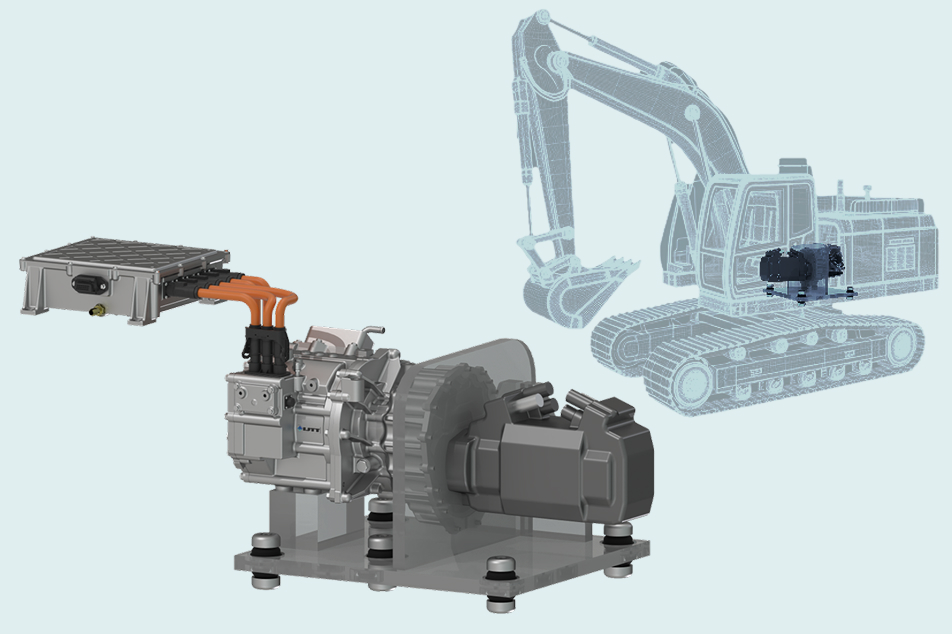

In addition to the e-Axle, IJTT is also developing e-Module, Regenerative Motor, and e-PTO to meet the electrification needs of commercial vehicles and construction machinery.

e-Module

Integrating transfer functions and compatible with 4-wheel drive systems

Adaptable to the unique working environments of construction machinery (angles of inclination, water resistance, etc.)

Regenerative Motor

Higher efficiency than conventional motors thanks to a regenerative mechanism

Optimized for use as e-Axle motor

e-PTO

Compact and quiet design, compatible with electric excavators, etc.