Initiatives for the Construction of IJTT’s ESG Advanced Model Plant

Next-Generation Plant Integrating Energy-Saving Technologies

The automotive industry is undergoing a once-in-a-century transformation.

IJTT is constructing a new plant in Kitakami with the aim of entering new growth fields.

This plant will manufacture parts for large robots indispensable for next-generation mobility systems, and will be ready to respond flexibly to changes in the market.

The manufacturing lines are being built mainly to parts for large robots that handle heavy parts such as batteries for assembly lines and logistics applications.

Overview of new plant

| Name | New Kitakami Foundry Plant |

|---|---|

| Location | 2-106-6 Goto, Waga-cho, Kitakami-shi, Iwate (on the premises of the Kitakami Plant) |

| Floor space | 25,850㎡ |

| Production capacity | Approx. 2,500 tons/month (two shifts, regular operation) (planned) |

Four innovations in plant construction

Changing consumption

The New Kitakami Plant introduces a state-of-the-art electric melting furnace in place of the conventional cupola furnace, greatly reducing the amount of heat escaping from the furnace. Furthermore, the double roof structure and lightweight aerated concrete (ALC) wall materials, as well as the use of fewer windows, improve thermal insulation and airtightness, thereby reducing the air conditioning load.

In addition, 3,500 solar panels have been installed on the roof to reduce CO2 emissions associated with electricity use.

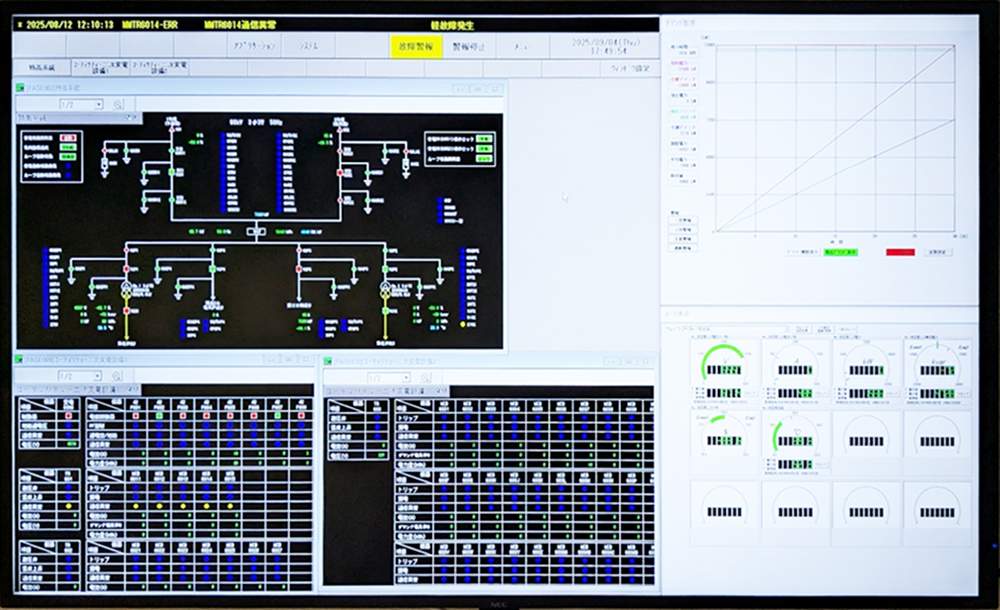

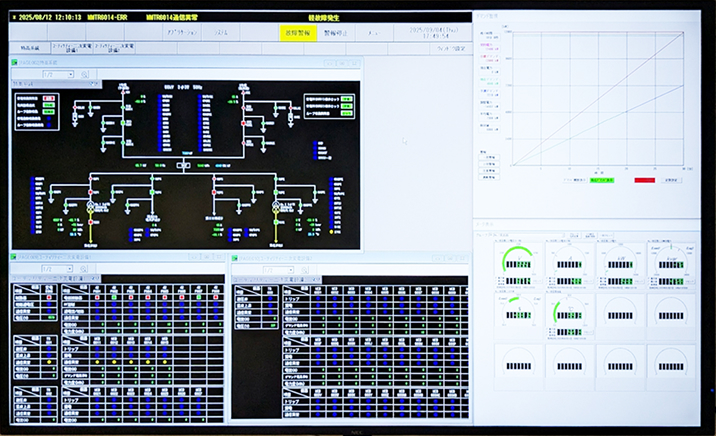

Changing administration

IoT and system technologies will promote visualization in five areas: equipment management, production control, quality control, worker administration, and consumption management. A traceability management system for individual products will also be implemented.

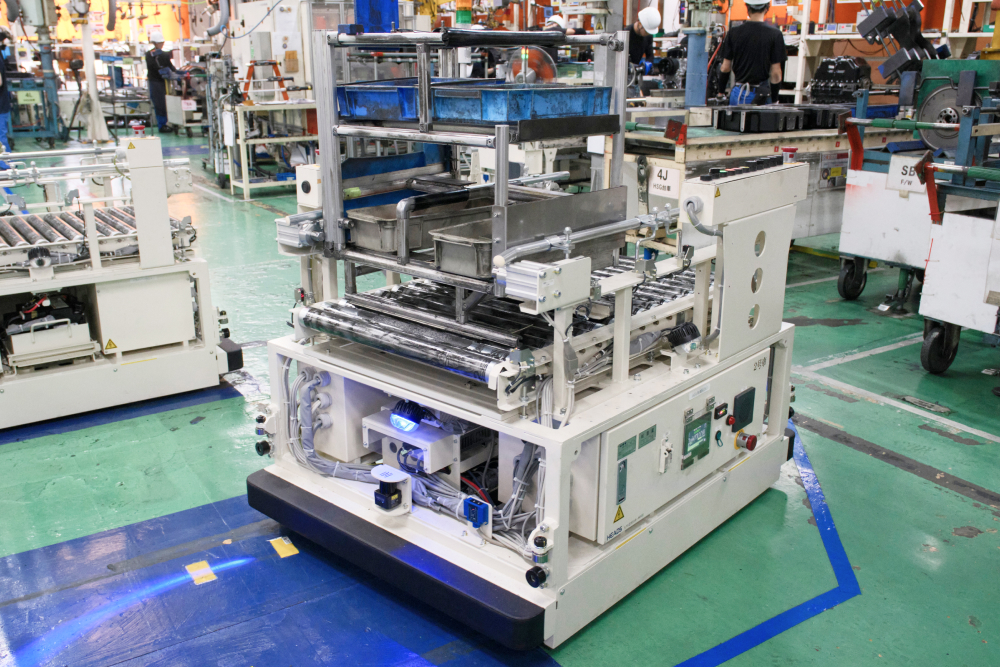

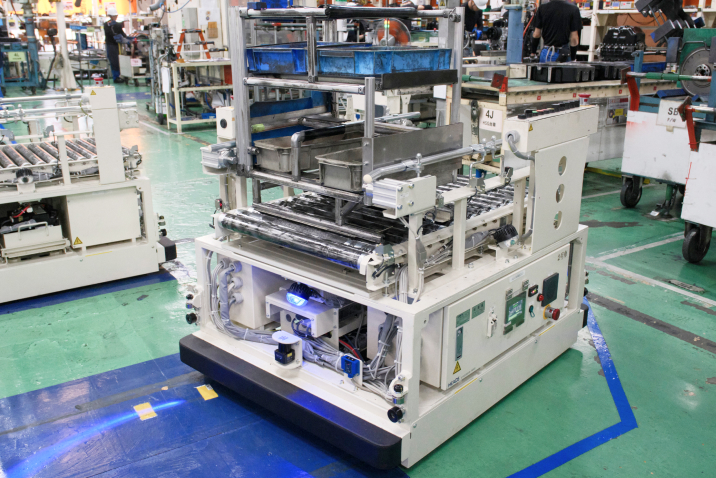

Changing on-premise logistics

Conventional transportation with forklifts will be eliminated where possible, and automated transportation robots (AGVs/AGFs) will be introduced. Six automated operation routes and an automated warehousing system will improve transportation efficiency, simultaneously saving labor and reducing CO2 emissions related to on-premise logistics.

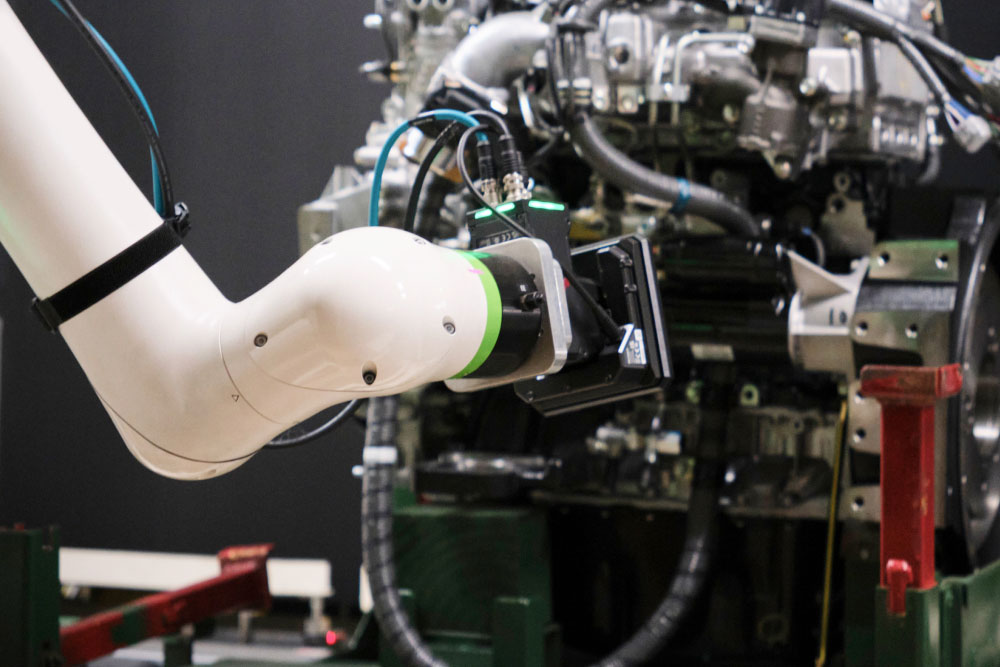

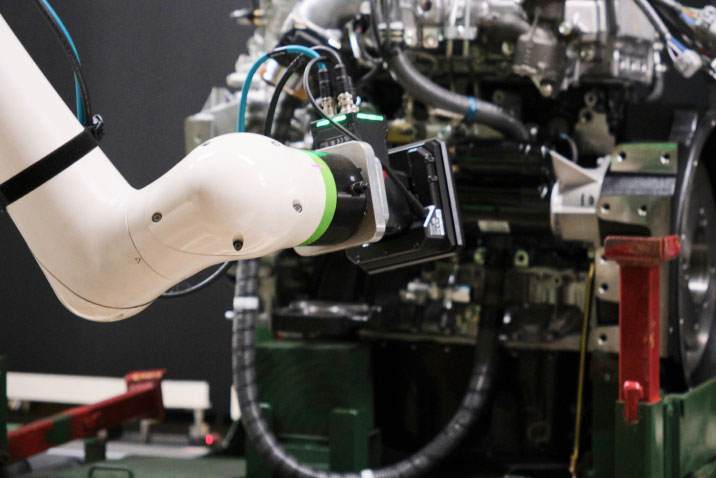

Changing the workplace

Approximately 50 industrial robots will be installed to replace human labor.

This will create a safer and more comfortable working environment for workers of all ages and genders.