Research and Development

In order to meet customers’ demands, we use a wide variety of analysis tools to maintain and improve quality, and to shorten development lead time. Also, with extensive R&D facilities, we develop high quality products while saving resources and ensuring safety.

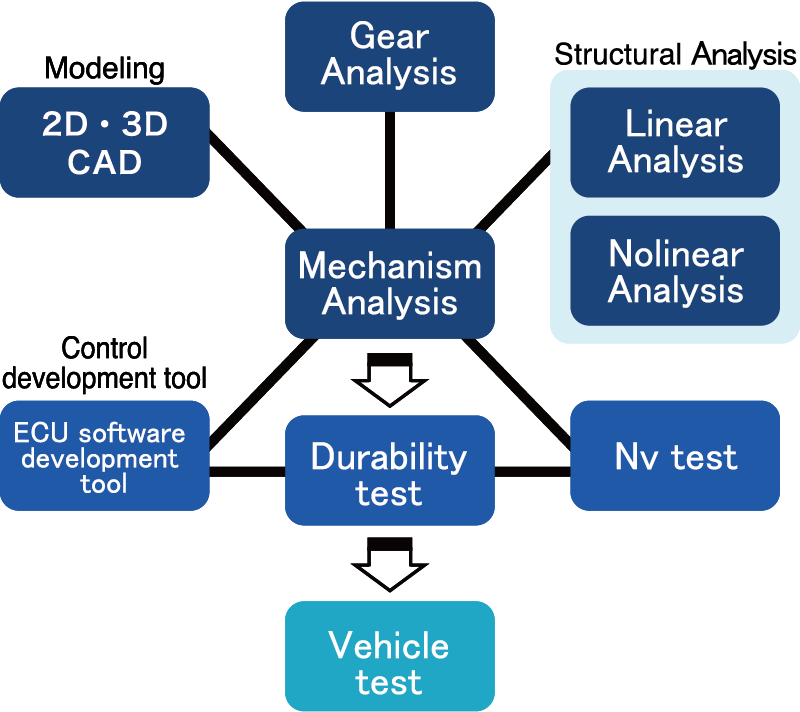

Analytical Tools

Test course at "Japan Automobile Research Institute"

Durability evaluation with actual vehiclein the low friciton test road and the rough road

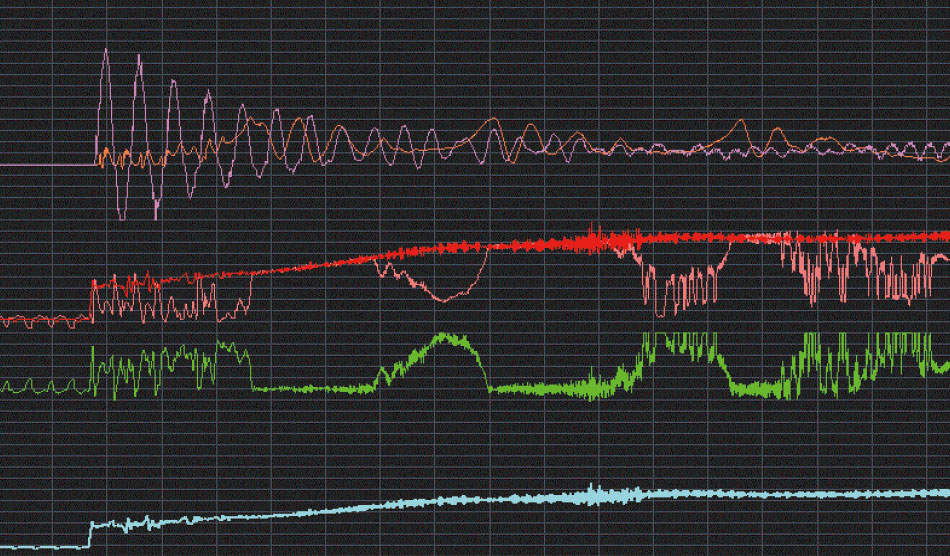

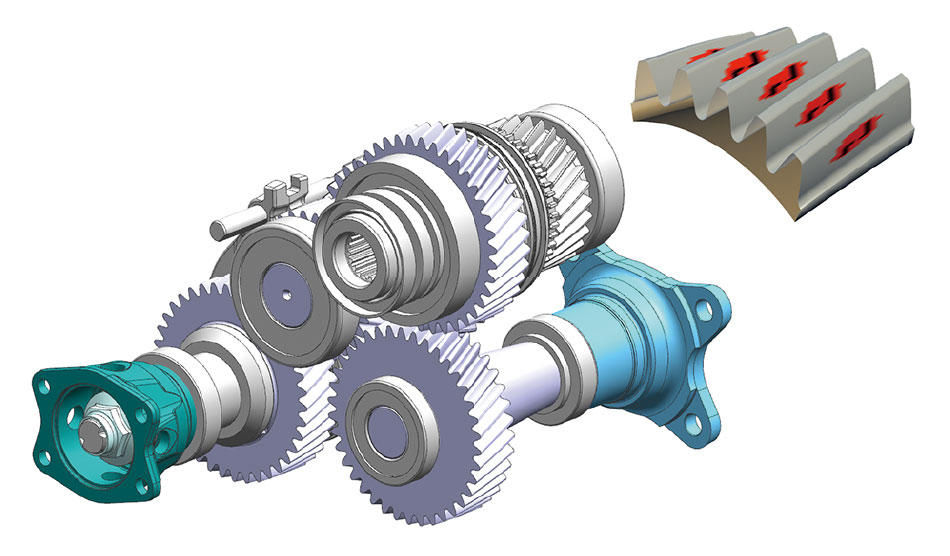

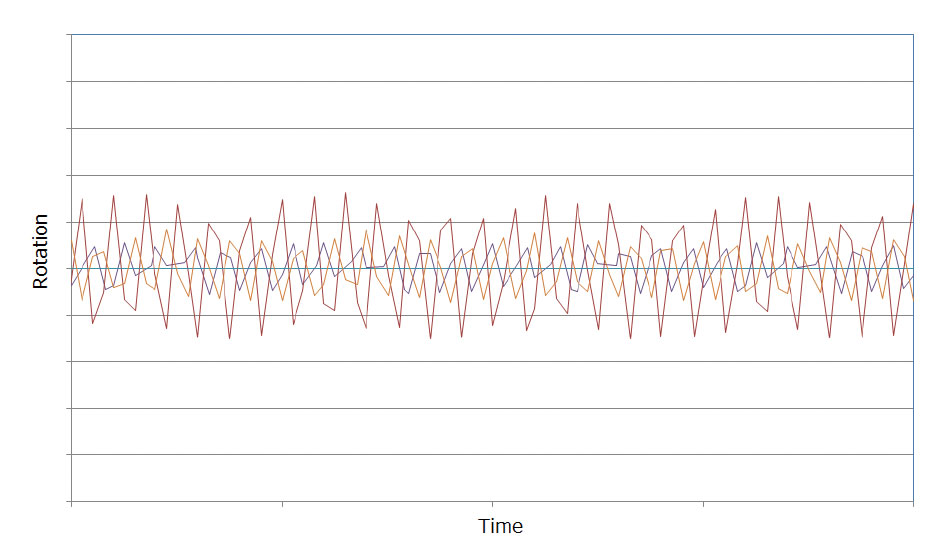

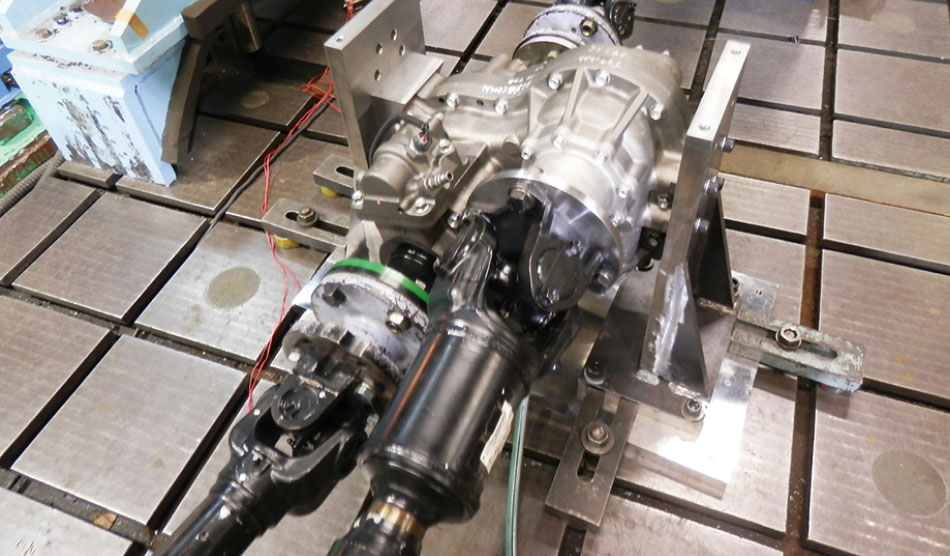

Mechanism Analysis

We model the driving mechanisms of automobiles and then predict and calculate the dynamic behavior such as movements and forces on computers.

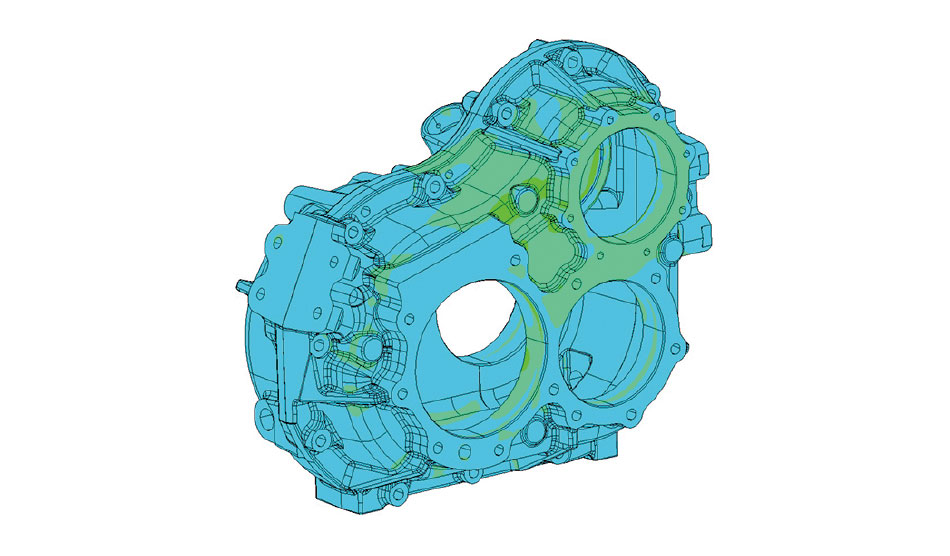

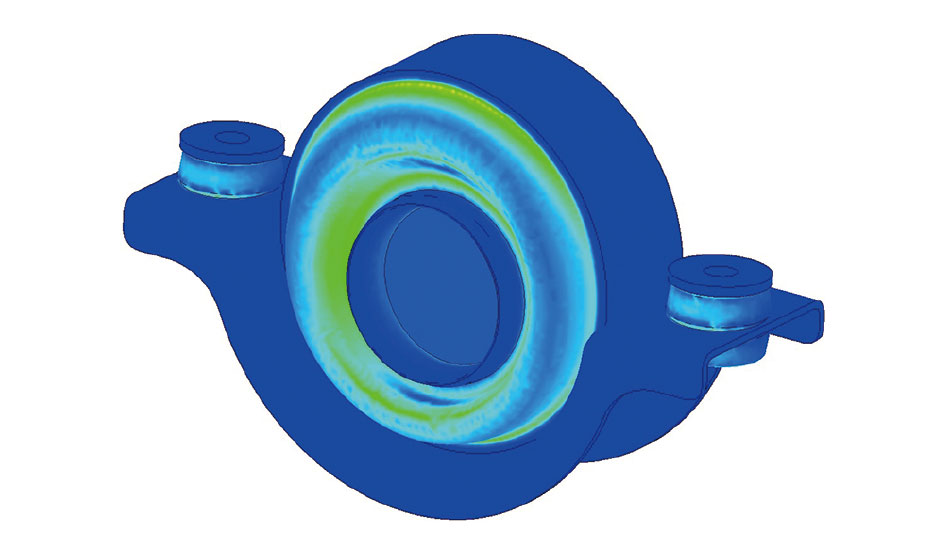

Structural Analysis

Structural deformation and stress due to external and internal forces are quantitatively analyzed.

Linear Analysis

Nolinear Analysis

Modeling

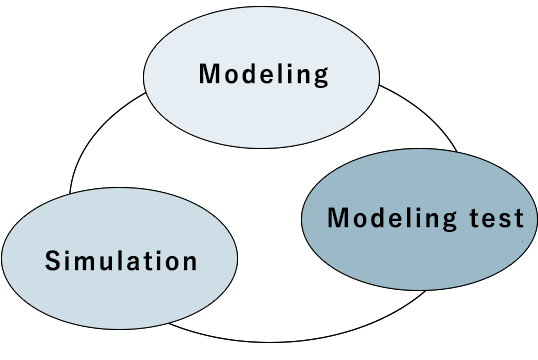

We achieve shorter delivery lead time and streamlining through systematization of the development process by using tools such as 3D simulation software and concurrent engineering.

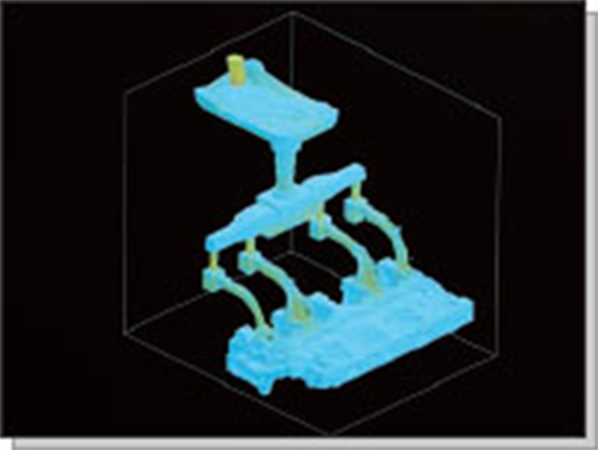

Example: casting

Modeling

Build prototypes of casting molds on computers.

The shape of the model (object) is created with 3D graphics. The decision process for the coordinates of each vertex and the parameter of equation which defines borders and surfaces can be visually recognized, and also the comparison with other processes can be easily done with numerical data.

Simulations

We analyze the flow of molten metal to sand mold, the temperature of molten model and the initial solidification point. By doing so, we can evaluate the validity of our design and mold plan before the prototype manufacture and furthermore, we are guided to optimized design value such as shapes (dimensions) and material components for the product.

Modeling inspection

By comparing prototype data acquired through a 3D measurement machine with simulation results, we evaluate any discrepancies. Results are fed back to modeling to pursue further accuracy.

R&D Facilities

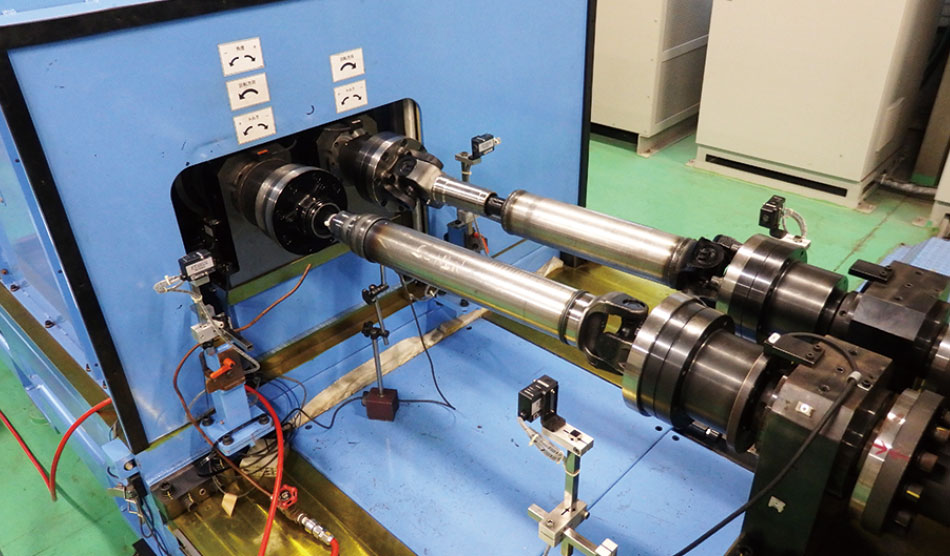

Rotational vibration testing machine

Static torsional testing machine

Dynamic spring testing machine

EPMA electron microscope

Exhaust simulator

Sand 3D printer